Black Dragon Forge

Salamander Super Graphite Casting Crucible (A10)

Salamander Super Graphite Casting Crucible (A10)

Out of stock

Couldn't load pickup availability

SHIPPING / DELIVERY

SHIPPING / DELIVERY

Not applicable to Digital Goods or Class Bookings.

Local Shipping:

- We currently only offer shipping within South Africa using The Courier Guy.

- Shipping is calculated at checkout and is based on your physical delivery address and the weight of the ordered goods.

- We ship within 24 hours from order placement.

- Delivery by The Courier Guy is normally within 3 business days from order collection.

- You will receive an email with your order tracking information as soon as the order is processed.

- All real-time order tracking is done online, via The Courier Guy website.

International Shipping:

- International customers can arrange their own courier services to collect from the Black Dragon Forge Workshop in Lanseria.

In the world of metal casting, precision, reliability, and quality are non-negotiable. Whether you're working with precious metals, ferrous alloys, or non-ferrous materials like aluminum, copper, brass, or bronze, the choice of crucible can make all the difference. Meet the Salamander Super Graphite Casting Crucible, a high-quality ceramic bonded clay graphite crucible that's set to revolutionize your metal casting experience.

The Power of Salamander Super

Unmatched Performance

Salamander Super Graphite Crucibles are designed to excel in fuel-fired furnaces, including our top-of-the-line Black Dragon Casting Furnaces. These crucibles are not your run-of-the-mill foundry tools. They offer unparalleled performance, ensuring that your metal melts cleanly and consistently, every time.

Temperature Range

The Salamander Super Crucibles thrive in the heat, with a typical metal casting temperature range of 850 – 1600°C (1562 – 2912°F). No matter how demanding your metal casting needs are, these crucibles have got you covered.

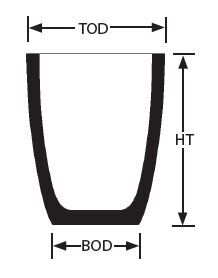

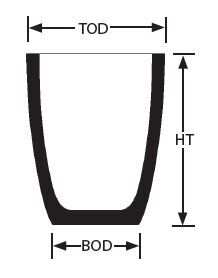

Technical Specifications

A10 Crucible

- Top Outside Dimension (TOD): 160 mm

- Bottom Outside Dimension (BOD): 110mm

- Height (HT): 200 mm

- Brimful Capacity: 2.4 Liters

- Weight: 2.9 kg

The A10 Crucible isn't just any crucible; it's a precision tool that holds just over 20.16 kg of bronze. Let's take a look at its material capacity based on its 1.2-liter volumetric capacity:

- Aluminium: 6.34 kg

- Copper: 21.37 kg

- Brass: 20.16 kg

- Silver: 25.22 kg

- Gold: 46.32 kg

What's in the Box?

1 x A10 Salamander Super Casting Crucible

Shipping Made Simple

Getting your Salamander Super Graphite Crucible to your workshop is hassle-free. We offer standard shipping for just R 150.00, calculated at checkout for your convenience. Delivery is managed by The Courier Guy, with delivery times ranging from 2 to 5 business days, depending on your location.

Uncompromising Quality

Salamander Super Casting crucibles are manufactured from premium grade raw materials under an ISO 9001:2000 quality management system. You can trust in the quality and reliability of every crucible.

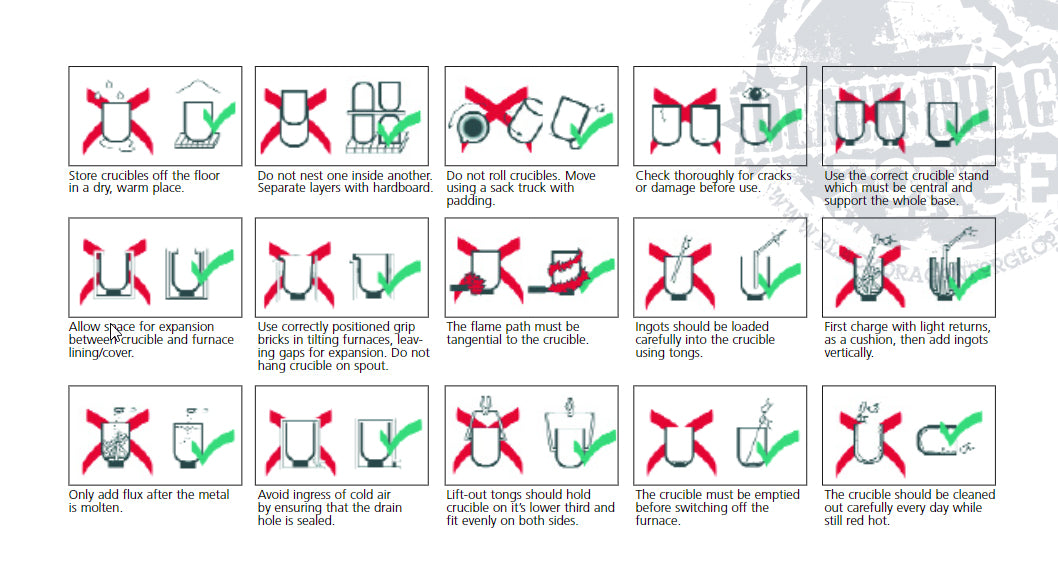

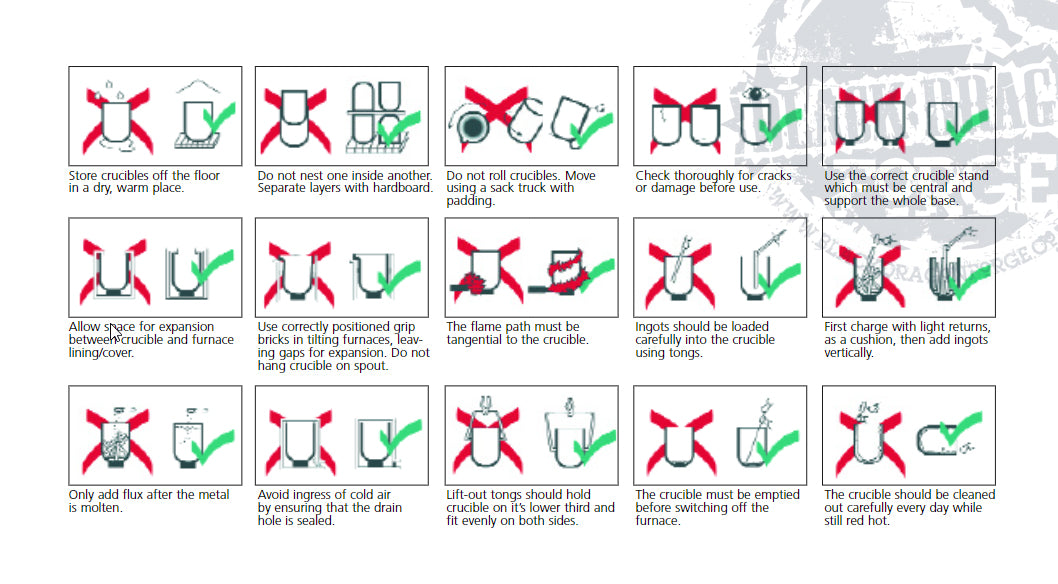

Preheating / First Use

To ensure the longevity of your crucible, follow these essential preheating steps:

- Preheat the empty crucible to minimize temperature gradients.

- If there's a risk of moisture absorption, heat the furnace to around 200ºC until moisture is eliminated.

- Heat the new crucible evenly to 600ºC on low power.

- Ramp up the heat to reach a uniform bright red condition (around 900ºC / 1650ºF).

- Charge your crucible with metal, ensuring the body temperature matches or slightly exceeds the molten metal temperature.

Charging

Once your crucible is preheated and ready, it's time to charge and melt. Here are some tips:

- Charge light scrap and returns first to create a cushion for heavier material.

- Use tongs to charge ingots and place large pieces vertically to allow for expansion.

- Add flux only when the metal is molten.

Cleaning Out

To maintain optimal performance, clean your crucible carefully between melts while it's red hot. This ensures the removal of any corrosive slag buildup.

Safety First

Remember, safety is paramount. Always wear proper safety clothing, and be vigilant about keeping moisture away from the melt. Additionally, make provisions underneath the furnace to catch any discharged metal.

In conclusion, the Salamander Super Graphite Casting Crucible is your ticket to achieving impeccable metal casting results. Its unmatched performance, quality, and reliability make it the go-to choice for professionals in the field. Invest in the Salamander Super, and elevate your metal casting game today.

Care

Frequently Asked Questions (FAQs)

1. How do Salamander Super Crucibles compare to standard foundry crucibles? Salamander Super Crucibles are known for being cleaner and more versatile, capable of handling a wide range of metals while maintaining exceptional performance.

2. Can I use Salamander Super Crucibles for precious metals? Absolutely! These crucibles are suitable for both precious and non-precious metals, offering the same level of quality and consistency.

3. What's the significance of preheating a new crucible? Preheating helps eliminate temperature gradients and moisture absorption, ensuring the crucible is ready for efficient and safe use.

4. How should I clean out a crucible between melts? Cleaning out a crucible while it's red-hot is essential to remove any corrosive slag build-up, maintaining its performance.

5. Is safety gear essential when working with Salamander Super Crucibles? Safety should always be a priority. Proper safety clothing must be worn to protect against potential hazards in the metallurgical process.